WHY IS LIQUID BUTYL RUBBER THE BEST CHOICE?

If you are not using Liquid Butyl Rubber your roof is not getting the best roof coatings it deserves. Over a 25 year history of success, it has proven to be the best and most versatile coating on the market.

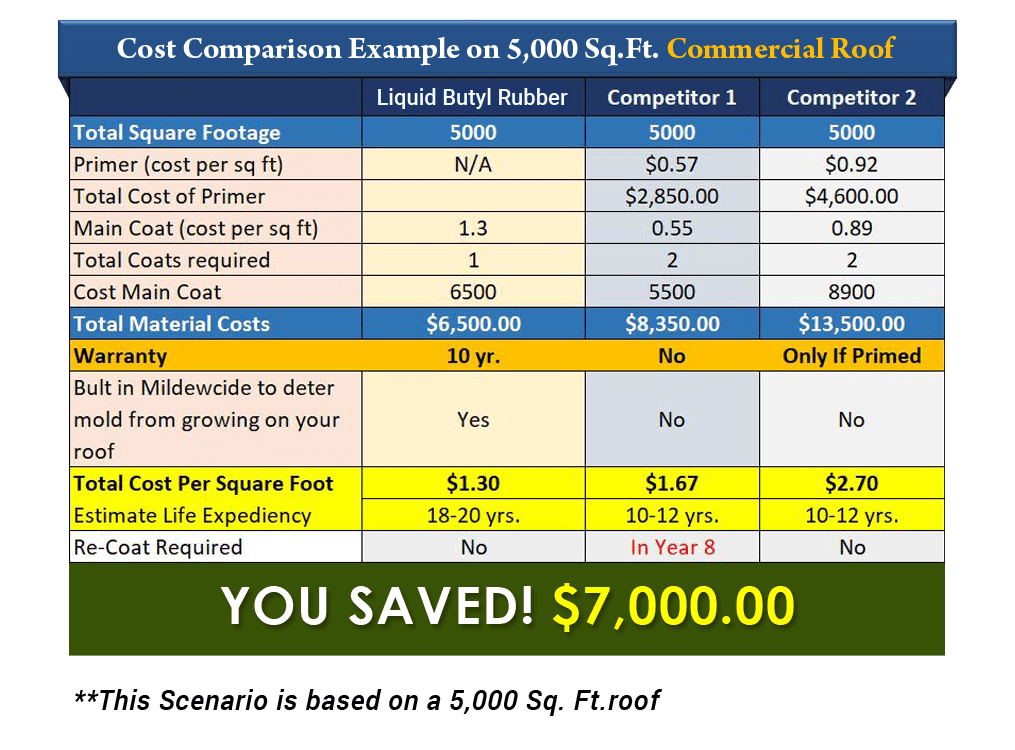

When looking for a long-term solution to your roof leak or extending your roof's life another 18-20 years, it is critical to choose the correct product the first time, so you don’t have to repeat the process later. We outlined several key benefits and characteristics of our Liquid BUTYL Rubber in the above bullet points. Equally important is looking at the overall cost. For example, what is cost per square foot and the resulting mil rate when dry? The thicker the mil rate the more protection and years added to your roof’s life. Does it require a primer or multiple coats? Why add unnecessary weight to a roof by using multiple-coat systems? These questions will not only determine the overall price you are paying for the product but also the additional installation costs assuming you are not applying it yourself. Our Liquid Butyl Rubber is a one-coat process, saving you time and money. There are no primers needed, so when you add up the cost of other systems that require primers and multiple coats, you have far exceeded the cost of Liquid Butyl Rubber. Also, our product is a solvent-based system not water-based making our product a superior choice. Why? Because Solvent-based coatings are significantly less susceptible to climate conditions, freezing temperatures and have a very high resistant to extreme weather conditions. Liquid Butyl Rubber will withstand ponding water literally 365 days a year! So, for everyone with a flat roof the choice should be clear.

Liquid Butyl Rubber has a thicker consistency that other coatings and results in a 20-mil film thickness. Other coatings may require 2 or 3 coats to achieve the same thickness. One of the main characteristics that makes Liquid Butyl Rubber so unique is in the chemistry of the drying process. As the product dries it chemically cross-links, creating a chemical bond whereby our coating and your roof fuse together to literally will become one in the same. Also, during the drying process the product will force out, and up to the surface, what would otherwise be trapped air (in other types of roof coatings). This is the reason other coatings have a tendency to crack after a few years especially elastomerics and water-based coatings. Our Liquid Butyl Rubber has a 500% elongation and over 1520 psi tensile strength allowing it to handle any roof that expands and contracts due to temperature changes. When the product dries what you have is a smooth seamless membrane.

Liquid Butyl Rubber can be applied directly on more types of roofs than other coatings on the market without the need for special primers. It has been the #1 roof coating recommended time and again by contractors throughout the USA. It is an economical and long-lasting solution, a proven alternative to roof replacement.